I. Equipment Overview

Scope of Application: Aluminum shell battery filling process, applicable battery models: external dimensions thickness 50-75mm, width 100-180mm, height 65-220mm

II. Process Flow

Manually place the battery cell

Align the filling nozzle with the filling hole

Press the foot pedal to start

The filling pump starts to fill the filling cup

The battery cell fixture moves to the static position

The static box descends

Vacuum/positive pressure is applied

Cycle according to the preset number of times

The static box rises

Move the fixture back to its original position

Manually unload the material

III. Technical Parameters

| No. | Equipment Parameter | Parameter | Remarks |

|---|---|---|---|

| 1 | External dimensions | Length 1400mmXWidth 1200mmXHeight 2200mm | Subject to the actual product |

| 2 | Upper and lower storage tanks | Size 200mm100m110mm (lengthwidthheight) | Capacity 2L |

| 3 | Fixture | The tray can hold 4 batteries (square aluminum shell batteries) | |

| 4 | Electric pump | 150g ceramic single-head electric pump, no dynamic sealing ring | Single pump head output liquid 10-150ml adjustable |

| 5 | Single pump accuracy | The filling pump accuracy is ±0.75%. | |

| 6 | Single pump size | 480mm150mm160mm (reference external dimensions) | Subject to the actual product |

| 7 | Power supply | 380V/50Hz | Subject to the actual product |

| 8 | Rated power | 3.5KW | Subject to the actual product |

| 9 | Uptime | ≥97% (faults caused by the equipment, excluding wearing parts) |

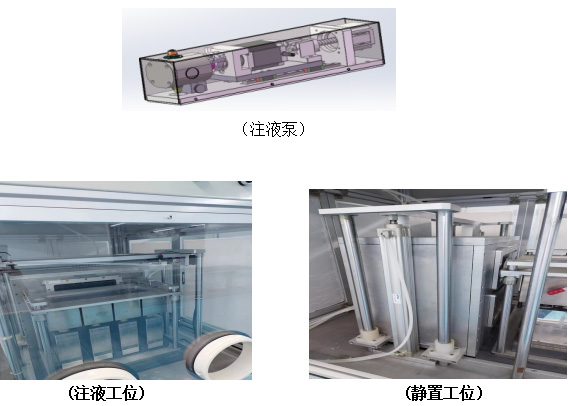

IV. Schematic Diagram of Filling Components Distribution

Filling pump (picture for reference only) Model: YK-ZYB-150g Digital variable pump, parameter adjustment, no need to hand tighten screws; Maximum filling rate per second: 600g; Accuracy: single shot accuracy ±0.75% Control method: PLC automatically calculates the filling volume, and fills multiple times if the set range is exceeded.

V. Main Equipment Components Brands

| No. | Name | Quantity | Remarks |

|---|---|---|---|

| 1 | Controller (PLC) | Siemens/Omron/Panasonic | 1 set |

| 2 | Human-machine interface | Siemens/Weilon/Xi'an Control | 1 set |

| 3 | Stepper motor | Leishi/Qinglan | 2 sets |

| 4 | Stepper drive | Leishi/Qinglan | 2 units |

| 5 | Single-head pump | Yanko | 1 unit |

| 6 | Pneumatic ball valve | NANVA /ZKV/ChuanNai | 1 set |

VI. Spare Parts List

1. Spare Parts

| No. | Name | Material | Model | Quantity |

|---|---|---|---|---|

| 1 | Chamber sealing ring | EPDM | 10*10 | 1 standard, 1 extra |

| 2 | X-type sealing ring | EPDM | 49.52*2.62 | 4 standard, 4 extra |

| 3 | End cap sealing ring | EPDM | Inner diameter 52*wire diameter 2.5 | 2 standard, 2 extra |

2. Wearing Parts

| No. | Name | Material | Model | Cycle |

|---|---|---|---|---|

| 1 | Chamber sealing ring | EPDM | 10*10 | 3 months |

| 2 | X-type sealing ring | EPDM | 49.52*2.62 | 4 months |

| 3 | End cap sealing ring | EPDM | Inner diameter 52*wire diameter 2.5 | 4 months |

3. Random Tool List

| No. | Name | Quantity/Unit | Specification |

|---|---|---|---|

| 1. | Allen wrench | 1 set/unit | 1.5-10mm |

| 2. | Open-end wrench |