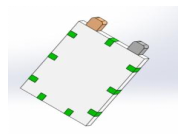

This machine is specifically designed and developed for stacking square lithium-ion polymer batteries using a Z-shaped stacking method. The machine uses a robotic arm to reciprocate and grab electrode sheets from the material box to the positioning station and then to the stacking station. It can realize automatic stacking, automatic counting, automatic pressing, and automatic battery cell output, enabling continuous production without interruption. The machine includes the following devices: a robotic arm reciprocating control device, a diaphragm rectifying control device, a positive and negative electrode material box supply device, an electrode sheet positioning device, a battery cell stacking device, and a battery cell transfer device.

Manually load electrode sheets into the material box → Robotic arm takes material from the positive and negative electrode material boxes → Robotic arm moves the positive and negative electrode sheets to the positioning platform → Automatic positioning of the electrode sheets → Robotic arm moves the positioned positive and negative electrode sheets to the stacking platform → Upon reaching the set number of stacked sheets, the robotic arm grabs the battery cell → Manual adhesive application

Material Specifications

| Item | Specification | Material | Incoming Material | Length (mm) | Width (mm) | Thickness (µm) | Inner Diameter (mm) | Max Outer Diameter (mm) |

|---|---|---|---|---|---|---|---|---|

| Positive Electrode | Sheet Material | 70-150 | 40-80 | 50~250 | —— | —— | ||

| Negative Electrode | Sheet Material | 70-150 | 40-80 | 50~300 | —— | —— | ||

| Separator | Roll Material | —— | 40-80 | 9~30 | φ76.2 | Φ250 |

Material Requirements

Electrode sheets must be uniformly coated, with a thickness error of less than 0.005mm, a high-width size error of less than 0.3mm, and wave edges of less than 1mm (to ensure proper sheet positioning).

The burrs on the edges of electrode sheets and tabs must be less than half the thickness of the separator.

The separator must be evenly wound, with a width error of less than 0.1mm and a taper error of less than 0.5mm.

The termination tape must be evenly wound, without noticeable taper, wrinkles, or warping.

Battery Cell Specifications

| Item | Specification |

|---|---|

| Battery Cell |  |

| Cell Length | |

| Cell Width |

Technical Parameters

| No. | Name | Parameter |

|---|---|---|

| 1 | Stacking Efficiency (seconds/piece) | Each piece 1.8~2.5 seconds, battery cell unloading time 10~15 seconds |

| 2 | Alignment Accuracy Between Electrode Sheets and Separator | Center deviation ±0.3mm |

| 3 | Alignment Accuracy of Separator Ends | ±0.5mm |

| 4 | Alignment Accuracy Between Adjacent Electrode Sheets | ±0.3mm |

| 5 | Overall Alignment Accuracy of Electrode Sheets | ±0.5mm |

| 6 | Number of Stacking Layers | Can be set within the height adaptation range |

| 7 | Appearance | Flat and wrinkle-free |

| 8 | Unloading | Robotic arm grabs the battery cell, manually taken out |

| 9 | Utilization Rate (excluding equipment-caused faults) | Over 98% |

| 10 | Qualification Rate (excluding incoming material defects) | Over 98% |

| No. | Name | Brand |

|---|---|---|

| 1 | PLC | Custom |

| 2 | Touch Screen | Custom |

| 3 | Servo Motor | Custom |

| 4 | Stepper Motor | Custom |

| 5 | Air Conditioning Unit | Custom |

| 6 | Pneumatic Components | Custom |

| 7 | Linear Guide Rail | Custom |

| 8 | Ball Screw | Custom |

| 9 | Photoelectric Switch | Custom |

| 10 | Vacuum Detection | Custom |

Prev :

Hot pressing test machineNext :

Polar die cutting machine