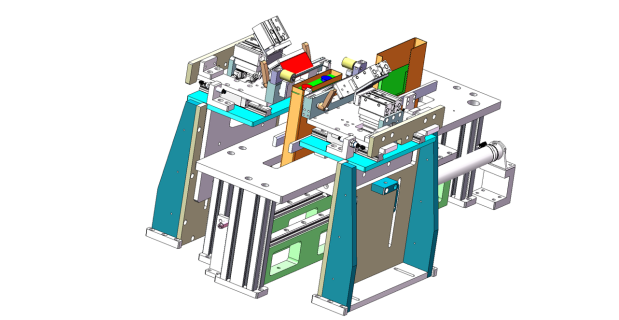

1. Equipment FunctionEquipment Function: Manually place the battery core and battery shell. Both are first dusted in the dust removal mechanism, then transferred to the casing position. The mechanism achieves semi-automatic casing of the battery core and shell.

Workflow Overview:Manually place aluminum shell into clamp → Manually guide battery core into mechanism → Positioning of dusted shell → Automatic advancement of aluminum shell → Automatic unloading.

2. Technical Parameters

Battery Core Size Compatibility: Aluminum shell dimensions Length * Width * Height (220mm * 135mm * 30mm)

Dust Removal Time: Adjustable from 1.0 to 5.0 seconds.

Aluminum Shell Buffer Quantity: ≥4 PCS

Casing Reserved Size: 3-5mm

Equipment Efficiency: 2 PPM

Operating Rate: 95%

Pass Rate: 99.5%

3. Main Component Configuration

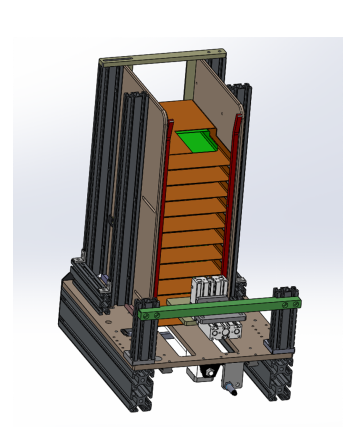

Shell Placement Mechanism

Aluminum Shell Positioning Dust Removal Mechanism

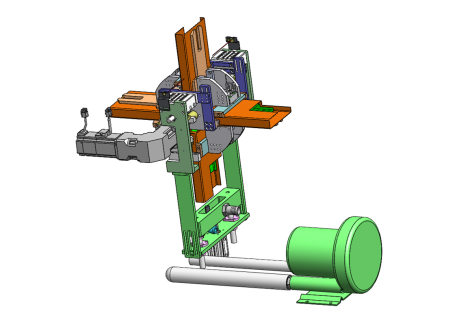

Casing Mechanism

4. Component Brands

4.1 Major Component Configuration

| No. | Name | Brand |

|---|---|---|

| 1 | Servo Motor | Inovance/Huichuan/Mitsubishi/Panasonic/Equivalent brands |

| 2 | Touch Screen | Weintek/Inovance/Equivalent brands |

| 3 | PLC | Mitsubishi/Inovance/Panasonic/Equivalent brands |

| 4 | High Pressure Fan | Yutian/Equivalent brands |

| 5 | Cylinder | SMC/Yadeke/Equivalent brands |

| 6 | Solenoid Valve | SMC/Yadeke/Equivalent brands |

| 7 | Ball Screw Guide Rail | HIWIN/KKT/Equivalent brands |

| 8 | Inductive Switch | Omron/Keyence/Equivalent brands |