This equipment is used for bonding the core of battery cells after welding the cell collector. The core involves flipping two cell bodies simultaneously and merging them into a vertical inverted state. The testing cylinder rises to test the positive and negative poles. Upon passing the test, the merged cells are flipped 90 degrees to a horizontal position. Side adhesive mechanisms then apply adhesive to bundle and secure the sides of the cells.

Power up and initialize equipment.

Wait for cells to enter the flipping fixture.

Audible prompt to insert liner.

Press start button.

Merge with flipping structure.

Testing phase.

Flip again.

Move to adhesive application position.

Apply adhesive on both sides simultaneously.

Proceed to next process or manual transfer.

3.1 Equipment Dimensions: LengthWidthHeight (1500mm1000mm2200mm).

3.2 Moving Module: Lead screw + double slide rail, 800mm stroke.

3.3 Flipping Structure: Cylinder + rack, cylinder diameter 63mm.

3.4 Tape Width: 20mm (customized).

3.5 Adhesive Length: 15-25mm ±0.5mm.

3.6 Adhesive Mechanism: Servo-controlled adhesive length, dual-axis per unit.

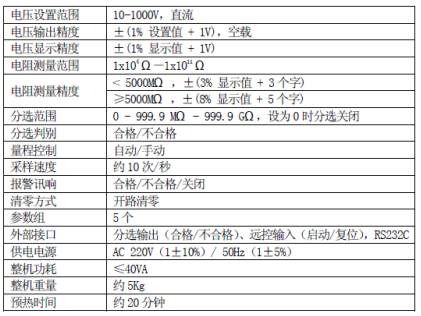

3.7 Insulation Tester: Changzhou Yangzi YD9820A digital display.

Moving Module: 1 set (Yenke).

Flipping Mechanism: 1 set (Yenke).

Adhesive Mechanism: 2 sets (Yenke).

Testing Unit: 1 unit (Digital screen Yangzi instrument).

| No | Name | Number | Parameters |

|---|---|---|---|

| 1. | Moving Module | 1 set | Yenke |

| 2. | Flip Mechanism | 1 set | Yenke |

| 3. | Bonding Mechanism | 2 sets | Yenke |

| 4. | Testing Section | 1 unit | Digital screen Yangzi Instrument |

4.1 Electric Core Platform Moving Module: Manually place the inner liner platform after placing the electric core platform to start the flipping angle, and move to the glue position after completion.

4.2 Structural Diagram:

| No | Name | Parameters |

|---|---|---|

| 1 | Linear Module | Stroke 810mm |

| 2 | Guide Rail | Shangyin/Shanglong |

| 3 | Servo Motor | Panasonic/Domestic |

4.3 Flip Mechanism: The mechanism combines and flips the electric cores.

4.4 Bonding Mechanism: After the mobile platform moves to the bonding position, bonding is carried out on both sides with three layers of adhesive each.

| No | Name | Parameters |

|---|---|---|

| 1 | Lifting Servo Motor | 400W, 2 sets |

| 2 | Pulling Servo Motor | 200W, 2 sets |

| 3 | Adhesive Cache Length | 10-150mm |

4.4 Testing Mechanism: After the electric cores are combined, the test cylinder pushes the test pin to contact the cover plate positive and negative poles, and the linked tester YD8290A/ST5520 tests whether the insulation value meets the process requirements.

| Serial No. | Component | Brand | Notes |

|---|---|---|---|

| 1 | PLC | Panasonic / Xinjie | Japan / China |

| 2 | Touch Screen | Weintek / Xinjie | China |

| 3 | Pneumatic Components | AIRTAC | China |

| 4 | Low Voltage Electricals | Chint | China |

| 5 | AC Contactors | Chint | China |

| 6 | Servo Motors | Panasonic / Domestic | China |

| 7 | Insulation Tester | Yangzi | China |

| Serial No. | Component | Quantity | Brand | Notes |

|---|---|---|---|---|

| 1 | Magnetic Induction Sensors | 2 pieces | Yadeke | |

| 2 | Slot-type Photoelectric Sensors | 2 pieces | Omron | |

| 3 | Blades | 2 pieces | Custom | |

| 4 | Testing Needles | 2 pieces | Custom |

| Serial No. | Tool | Specifications | Quantity | Notes |

|---|---|---|---|---|

| 1 | Hex Wrench | 1.5-10 | 1 set | |

| 2 | Open-end Wrench | 8mm-10mm | 1 piece | |

| 3 | Open-end Wrench | 10mm-12mm | 1 piece | |

| 4 | Adjustable Wrench | 250mm | 1 piece | |

| 5 | Phillips Screwdriver | 6*150mm | 1 piece | |

| 6 | Tool Box | ZS-430 double-layer | 1 piece | |

| 7 | Clock Screwdriver Set | 6 pieces | 1 set |

| Serial No. | Item | Description |

|---|---|---|

| 1. | Equipment Dimensions | Approximately 1500mm (L) x 1000mm (W) x 2000mm (H) |

| 2. | Power Requirements | 1) Single-phase AC 220V±10%, 50Hz, grounding: protective grounding >2) Equipment installation power: 2KW |

| 3. | Compressed Air | 1) Compressed air pressure: ≥0.6MPa, pressure fluctuation ±1% (clean air after water, oil, filtering, and stabilizing) 2) Compressed air consumption: 10m³/h, 1 interface per unit 3) Interface air pipe specifications: Φ10mm |

| 4. | Environmental Requirements | 1) Ambient temperature: Coating section 25±5℃ (according to buyer's process requirements) 2) Relative humidity: 10%~30%RCH (according to buyer's process requirements) 3) Cleanliness: Class 100,000 (according to buyer's process requirements) |

| 5. | Floor Requirements | 1) Equipment total weight: Approximately 0.5T >2) Cement or terrazzo flooring, flatness ±5mm/㎡, load capacity ≥350kg/㎡ |