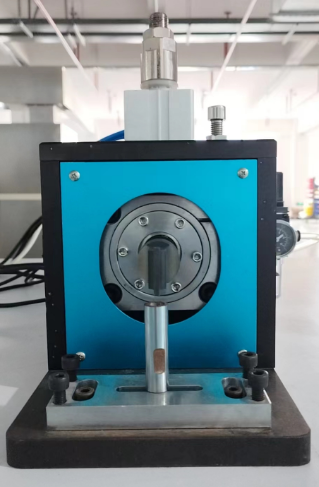

This machine is used for welding aluminum foil to aluminum lugs and copper foil to copper plated nickel or nickel lugs.

Set the equipment parameters according to the product process

Manually position the battery cell lugs and caps

Start the switch

The cylinder presses down for welding

After welding is completed, the cylinder rises

Manually remove the battery cell

| No. | Name | Parameter |

|---|---|---|

| 1 | Lug Welding Method | Horizontal |

| 2 | Welding Surface Life | ≥100,000 times |

| 3 | Welding Head Material | Imported powder alloy |

| 4 | Weld Height | 0~50mm |

| 5 | Distribution State of Weld Points/Patterns | Straight or herringbone pattern on the upper welding head, mesh pattern on the lower mold |

| 6 | Height of Welding Surface from Welding Head | 0~50mm adjustable |

| 7 | Usable Welding Surface of Welding Head | 4 |

| 8 | Power that Transducer Can Withstand | 1000W |

| 9 | Ultrasonic Frequency | 40KHz |

It adopts advanced constant current and constant pressure circuit technology, and the ultrasonic amplitude can be continuously adjusted.

It adopts intelligent ICS chassis control system with secondary ultrasonic function; system self-check on startup, intelligent segment vibration, automatic tracking.

The mechanical structure of the machine head adopts German X-rail structure with high precision.

Protection system:

Voltage protection system (power supply voltage range 220V~250V); does not affect the output power and working frequency of this machine during automatic constant voltage.

Overload protection system.

Overcurrent protection.

Automatic compensation for unstable power supply frequency.

Welding overload protection signal feedback.

| No. | Name | Brand |

|---|---|---|

| 1 | Cylinder | Yadake or equivalent brand |

| 2 | Solenoid valve | Yadake or equivalent brand |

| 3 | Welding head | Customized |

Power supply: AC220V/50Hz, power about 1KW.

Compressed air: 0.5–0.7Mpa.

Equipment specifications:

Equipment weight: approximately 50kg.

Generator dimensions: approximately L (0.55m) x W (0.3m) x H (0.55m).

Machine head dimensions: approximately L (0.5m) x W (0.2m) x H (0.4m).

Appearance color: light gray.

Environmental requirements:

Ambient temperature: 25±5℃.

Relative humidity: 30%–75%RCH, the site air should be dry and unobstructed, and there should be no acid and alkali corrosion.

Grounding: protective grounding.