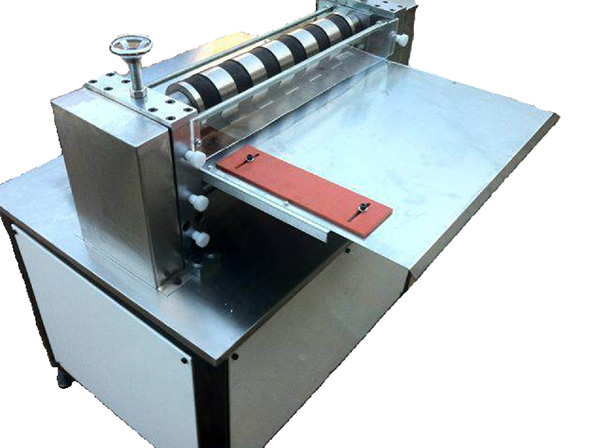

This machine is used for slitting and cutting positive and negative electrode sheets after battery coating.

Start the equipment

Manually position the electrode sheet

Manually feed the material

Automatic slitting

Manual collection

| No. | Name | Parameter |

|---|---|---|

| 1 | Substrate Thickness Range | Aluminum foil (Al): 11–30μm; Copper foil (Cu): 8–30μm; Including substrate 50–180μm |

| 2 | Substrate Width | 400mm |

| 3 | Machine Speed | 1–20m/min |

| 4 | Slitting Method | Longitudinal slitting with upper and lower circular blades |

| 5 | Blade Material | Alloy |

| 6 | Slitting Blade Diameter | Factory outer diameter Φ85mm, minimum grindable to working outer diameter: Φ75mm |

| 7 | Edge Trim Width | ≤3mm |

| 8 | Slitting Width Adjustment | 15–200mm |

| 9 | Roller Blade Compensation Method | "O" spring, 1mm compensation |

| 10 | Slitting Width Accuracy | ±0.2mm |

| 11 | Slitting Burrs | Electrode sheet burrs after slitting: Longitudinal burrs < 16μm (beyond electrode sheet direction), transverse burrs < 25μm (electrode sheet direction) |

| No. | Name | Brand |

|---|---|---|

| 1 | Circuit Breaker | Zhengtai or equivalent brand |

| 2 | Motor | Joint venture |

| 3 | Slide Block | Joint venture |

| 4 | Intermediate Relay | OMRON or equivalent brand |

| 5 | AC Contactor | Zhengtai or equivalent brand |

| 6 | Gearbox | Joint venture |

| 7 | Slitting Blade | Domestic alloy (customized according to customer requirements) |

Power Supply: AC380V/50Hz, power about 1KW.

Equipment Specifications:

Equipment weight: about 300kg.

Dimensions: about L (0.7m) x W (0.7m) x H (0.9m).

Appearance color: light gray.

Environmental Requirements:

Ambient temperature: 25±5℃.

Relative humidity: 30%–75%RCH, the site air should be dry and unobstructed, and there should be no acid and alkali corrosion.

Grounding: protective grounding.