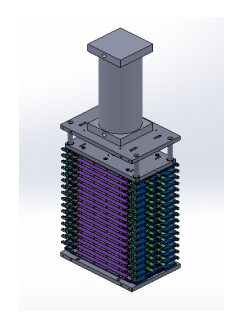

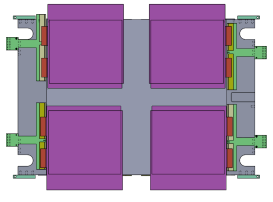

The equipment is used for the formation process of single-tab pouch lithium-ion batteries. It operates by clamping the cells between heated aluminum plates and conducting the formation process through rapid heat conduction. The cells are placed between the pressure plates and clamped using a cylinder mechanism. A single device has 256 points, three sets of fixtures, and each layer holds four batteries. The maximum charge and discharge current is 6A.

Preheat the machine.

Open the machine door.

Open the fixture.

Manually insert the batteries.

Close the machine door.

Cylinder clamps the cells.

Start the formation process.

Perform the formation process.

Formation process ends.

Cylinder resets and releases the cells.

Open the machine door.

Manually remove the batteries.

| Serial Number | Name | Code | Specification (mm) |

|---|---|---|---|

| 1 | Length | L1 | 70~150 |

| 2 | Width | W1 | 40~80 |

| 3 | Thickness | T | 4~12 |

| 4 | Tab Length | S | 10~20 |

| 5 | Minimum Tab Gap | W2 | ≥10 |

| 6 | Tab Width | W4 | 10~20 |

| Serial Number | Equipment Parameter | Description |

|---|---|---|

| 1 | Workflow Control Method | Cabinet Control |

| 2 | Charging Mode | Constant Current, Constant Voltage |

| 3 | Charge Termination Criteria | Voltage, Current, Time, Capacity |

| 4 | Discharge Mode | Constant Current |

| 5 | Discharge Termination Criteria | Voltage, Time, Capacity |

| 6 | Sampling Inspection Cycle | ≤3s |

| 7 | Voltage Measurement Range | 0~5V, Resolution 0.1mV |

| 8 | Battery Voltage Range | Charge: 04.5V, Discharge: 4.52V |

| 9 | Constant Voltage Range | 0~4.5V |

| 10 | Voltage Accuracy | ±2mV |

| 11 | Current Range | 0.01-6A, Resolution 1mA |

| 12 | Current Accuracy | ±(0.05%RD+0.05%FS) |

| 13 | Time Range | 0~30000 minutes, Time Unit is min |

| 14 | Time Accuracy | ≤±0.1% |

| 15 | Process Settings | Up to 32 steps and 256 cycles |

| 16 | Temperature Range | Room Temperature - 90℃ |

| 17 | Temperature Accuracy | ±3℃ |

| 18 | Initial Heating Time | ≤30 minutes (Target Temperature: 80℃) |

| 19 | Heating Method | Electric Heating |

| 20 | Pressure Range | 500~3000kg |

Language: Simplified Chinese.

Process Editing: Ability to set different processes according to battery models, including constant current charging (CCC), constant current and voltage charging (CCVC), rest, and constant current discharging (CCD).

Step Functions: Copy, paste, delete steps, move or delete single or multiple steps, and set up to 32 formation steps in each process.

End Conditions: Control each process's end condition by time, voltage, and current limits.

Support for Continuation: Manual pause, software closure, power interruption, equipment communication interruption, and abnormal stop continuation.

Data Storage: Local storage of detailed test data with options to view current and historical data and export data as Excel reports.

Capacity Sorting: Sort batteries into grades based on capacity.

Qualification Judgment: Judge qualification based on specified cycle capacity, voltage, time, etc.

Protection: Protect against step and global voltage, current, and temperature abnormalities with alarms.

Database Storage: Backend storage on a database server.

Offline Protection: Offline software protection.

Software Upgrades: Free upgrades.

Pressure Mechanism: Uses cylinder pressurization controlled by a PLC and electric proportional valve, allowing multi-segment pressure adjustments.

Heating Plate: Uses a silicone heating plate controlled by a PLC temperature module.

Tab Compression Block: Made of insulated injection-molded parts.

Compression Springs: Made of mold springs or 304 stainless steel springs.

Protection Functions:

Overvoltage, undervoltage, overcurrent, undercurrent, overcapacity protection.

Configurable voltage and current protection ranges.

High-level alarm lights indicating work status.

Emergency stop button to automatically open the fixture in case of emergency.

Smoke alarm stops the machine and triggers an alarm.

Continuation of unfinished processes after an alarm-induced stop without restarting from the beginning.

Continuation of work after communication recovery between lower and upper machines.

Overtemperature protection cuts off heating and formation processes and triggers an alarm when the set temperature is exceeded.

Continuation of current process step after unexpected power interruptions.

Automatic wait state during communication interruptions or PC failures, resuming the current process after communication recovery.

| Serial Number | Name | Specification | Quantity |

|---|---|---|---|

| 1 | Business Card Paper | Custom | 20 sheets |

| 2 | Circuit Board | Custom | 1 each (left and right) |

| 3 | Temperature Control Line | Custom | 1 line |

| 4 | Heating Plate | Custom | 1 plate |

| 5 | Silicone Plate | Custom | 1 plate |

Power Supply: AC380V/50Hz, approximately 17KW.

Compressed Air: 0.5~0.7Mpa.

Equipment Foundation Load: ≥1000Kg/m².

Equipment Specifications:

Weight: Approximately 1500kg.

Dimensions: Approximately L (2.4m) x W (0.8m) x H (2.33m).

Color: Light gray.

Environmental Requirements:

Ambient Temperature: 25±5℃.

Relative Humidity: 30%~75% RH; ensure dry, well-ventilated air without acidic or alkaline corrosion.

Grounding: Protective grounding.

Prev :

Vacuum Pre Sealing MachineNext :

Vacuum standing box