1. Equipment Overview

The traction electrode sheet is compacted to a predetermined thickness or density by applying pressure through the gap of the compression rollers. This ensures that the lithium battery produced using the rolled electrode sheet achieves the designed or predetermined volumetric energy density and battery performance.

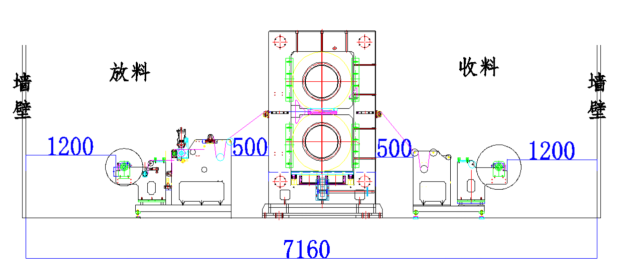

Tension Unwinding → Deviation Correction → Splicing Platform → Edge Trimming and Dust Removal → Electrode Buffering → Rolling (Upper and Lower Rollers with Scraper) → Electrode Buffering → Deviation Correction → Tension Rewinding

| No. | Name | Parameters |

|---|---|---|

| 1 | Roll Dimension | Φ400mm×450mm |

| 2 | Roll Speed | 2~12r/min, infinitely adjustable |

| 3 | Rolling Linear Speed | 2~14m/min |

| 4 | Maximum Working Pressure | 200T |

| 5 | Maximum Rolling Force | 4000KN (400 tons) |

| 6 | Roll Surface Finish | Surface roughness of 0.02μm (near mirror) |

| 7 | Roll Heat Treatment | Roll hardness: HRC66-68, roll tempering: HB280-300, quenching depth ≥18MM, roll cylindricality ≤±0.001mm |

| 8 | Roll Gap Adjustment | Automatic locking device, 0--2mm adjustable |

| 9 | Electrode Rolling Method | Continuous rolling with gap and pre-pressure; pre-pressure applied hydraulically, maximum pre-pressure: 6000KN, using oil pressure constant pressure, gap adjustment range: 0-2mm |

| 10 | Roll Drive Method | Universal coupling separate drive for upper and lower rolls, stable operation without impact or crawling |

| 11 | Oil Pressure Power | Electric oil pressure system |

| 12 | Edge Cutting Tool | Assembled structure, adjustable width, suitable for 50~400mm edge |

| 13 | Unwinding/Rewinding Machine Performance Indicators | a: Electrode Parameters: core φ76 mm, max. unwinding diameter φ400 mm, max. width 400 mm; b: Unwinding Parameters: unwinding tension control accuracy 5%, tension adjustment range 0.5~12.5Kgf; c: Edge Control: deviation correction accuracy ≤±0.2mm; d: Tension Adjustment: 25N |

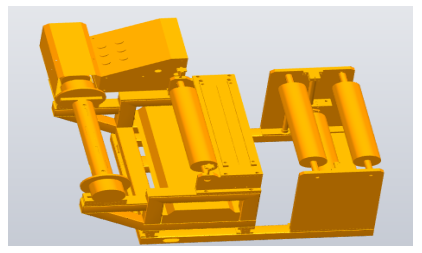

The electrode continuous rolling production line consists of an unwinding machine, hydraulic roller machine, rewinding machine, electrical control system, electric booster pump, deviation correction device, etc.

This device supports the coil material to be rolled and transports it to the rolling mill for rolling. It consists of an integral upright plate installation (thickness 20mm), CNC machining center production, hard chrome-plated frame, linear bearings, deviation correction device, air expansion shaft, magnetic powder brake and tension controller, guide roller, etc.

Main Technical Parameters:

Unwinding Shaft: Diameter Φ76mm, effective length 500mm; air expansion shaft with control valve, equipped with an air gun

Max. Unwinding Diameter: Φ400mm

Unwinding Load Capacity: 300kg

Tension Controller: 0~25N.m (adjustable), using French KDT tension control device

Deviation Correction Device: Using Dongdong control system, controller accuracy ±0.2mm (Re).

Splicing platform: Consists of splicing plate, pressure bar, cylinder, guide rail, integrated with the unwinding machine;

Splicing Method: Assisted by cylinder-driven pressure bar

Splicing Width: 400mm

Edge trimming and dust removal machine consists of the machine frame, upper cutter, lower cutter, brush roller, vacuum cleaner (provided by user), floating roller, guide roller, etc. It trims off the uncoated areas and edge protrusions to prevent uneven stress during rolling, ensuring a flat electrode sheet. The edge trimming knife is adjustable, with a wide application range.

Main Technical Parameters:

Knife Speed (max): 40 r/min

Edge Width: 300 mm~450mm (continuously adjustable)

Motor Power: 0.75 KW (three-phase 380V 50Hz)

Weight: Approximately 0.4 T

The vibration reduction device consists of a frame, fixed guide roller, floating guide roller, linear guide rail, etc. It is used to reduce electrode sheet vibration in gap rolling, preventing sheet breakage.

Quantity: 2 units, one set before the rolling mill and one after, front buffer integrated with edge trimming, rear buffer integrated with rewinding machine.

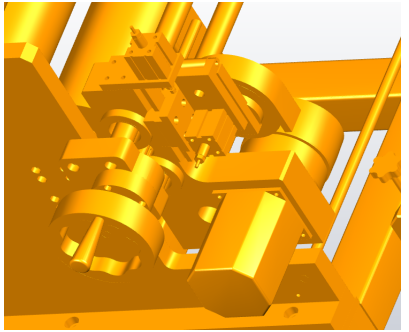

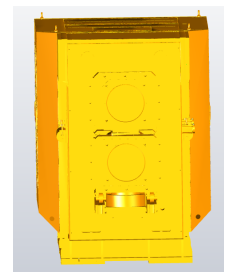

The rolling mill is the main equipment in the continuous rolling production line, consisting of a gantry frame, universal couplings, motor reducer, electric booster system, gap adjustment system, electrical control system, feed guard plate, and roller cleaning mechanism. It ensures the electrode sheet reaches the desired density and thickness. The device uses a ball screw wedge block gap adjustment structure, and the rolling speed is infinitely adjustable via a frequency converter.

Main Technical Parameters:

Overall Dimensions (LWH): Approx. 2850mm×850mm×1500mm

Roll Specifications (Roll Surface DiameterRoll Surface Width): φ400450mm

Effective Roll Width: 400mm

Roll Speed: 2~12rpm, infinitely adjustable

Roll Material: 9Cr3Mo (product of Xingtai Roll Co., Ltd.)

Roll Surface Hardness: HRC≥66~68

Roll Tempering: HB280-300

Quenching Layer Depth: ≥18mm

Roll Cylindricity: ≤±0.001mm

Roll Surface Roughness: Ra=0.04

Roll Chrome Plating Thickness: ≥0.18mm

Roll Surface Cleaning: Adjustable blade mechanism, scraper type structure, automatic removal of adhered material with collection box, cleaning blade for both upper and lower rolls;

No-load Cylindricity: ≤±0.002mm

Drive Method: Universal coupling drive

Main Motor Power: 8kW (2*4KW 380V 50Hz)

Hydraulic Cylinder Specifications: Cylinder diameter φ200mm, stroke 10mm

Max. Rolling Force: 4000KN

Roll Line Pressure: 0.45~4.5t/cm

Gap Adjustment Method: Central wedge block adjustment, hydraulic constant pressure.

Gap Adjustment Range: 0~3mm

Roll Bearings: P5 grade high-precision bearings

Equipment Layout: Drive power part on the left side of the feed end

The rewinding machine rolls the electrode material onto the core shaft after rolling. It consists of a frame, linear bearings, deviation correction device, air expansion shaft, rewinding motor, magnetic powder clutch, and tension controller, guide rollers, etc.

Main Technical Parameters:

Rewinding Shaft: Air expansion shaft diameter: Φ76mm, effective length: 400mm, air expansion shaft with control valve, equipped with an air gun

Max. Unwinding Diameter: Φ400mm

Max. Load Capacity: 400kg

Tension Controller: 0~25N.m (adjustable), using French KDT tension control device

Deviation Correction Device: Using Dongdong control system, controller accuracy ±0.2mm (Re).

The electrical part of the equipment is controlled by the operation panel on the control cabinet, consisting of a rolling main motor frequency converter, rewinding motor, electric pump booster system, magnetic powder brake, magnetic powder clutch, tension controller, etc.

The unwinding machine controls unwinding tension via a tension controller and magnetic powder brake.

The rolling mill is driven by the main motor (variable frequency motor 11kW*2) through a reducer and universal coupling, with frequency converter control for variable speed.

The rewinding machine drives the rewinding shaft via a rewinding motor. The tension controller controls rewinding tension through a magnetic powder clutch.

The electric pump booster system adjusts and controls the hydraulic cylinder's lifting via a touch screen HMI, driving the rolling lower roll's lifting.

The unwinding/rewinding deviation correction control is completed by driving motors for the unwinding and rewinding deviation correction devices.

The hydraulic pressure of the rolling rolls is adjusted via the HMI.

The rolling roll movement value is displayed on the HMI screen.

The HMI inputs adjust the gap of the hydraulic rolling mill rolls.

| No. | Name | Brand |

|---|---|---|

| 1 | Touch Screen | Weintek/Xinjie or equivalent |

| 2 | Servo Driver | Panasonic/Inovance/Xinjie or equivalent |

| 3 | Liquid Pressure Sensor | TPT505 or equivalent |

| 4 | Roll Frequency Converter | Hypmont or equivalent |

| 5 | PLC | Mitsubishi/Xinjie/Panasonic or equivalent |

| 6 | Electric Booster Pump | Rongfeng or equivalent |

| 7 | Reducer | Outai or equivalent |

| 8 | Unwinding/Rewinding Deviation Correction | Dongdong or equivalent |

| 9 | Driver | Dongdong or equivalent |

| 10 | Tension Control System | French KDT or equivalent |

| 11 | Bearings | P5 grade high-precision roll bearings or equivalent |

| 12 | Edge Cutting Tools | Imported carbon steel knives |

| No. | Name | Model |

|---|---|---|

| 1 | Magnetic Switch | CMSG-020 |

Power Supply: AC380V/50Hz, power approx. 10KW.

Compressed Air: 0.5~0.8Mpa, flow rate: 0.04M3/min.

Equipment Specifications:

Equipment Weight: Approx. 5 tons.

Dimensions: Approx. L (2.85m) x W (0.85m) x H (1.5m).

Appearance Color: Light grey.

Environment Requirements:

Ambient Temperature: 25±5℃.

Relative Humidity: 30%~75%RCH, ensure site air is dry and well-ventilated, free from acid and alkali corrosion.

Ground Connection: Protective grounding.

Prev :

Sheet cutting machineNext :

Transfer coater