Device Name: Rechargeable Battery Testing Formation Capacity Grading Equipment.

Device Model: YK-LKFR128CH-5V30A.

Device Application: Used for charging and discharging test and capacity grading of square aluminum shell lithium-ion batteries.

Scope of Application: Battery height 65~220 Positive and negative pole spacing 40~90

Device Color: Computer white or customer specified.

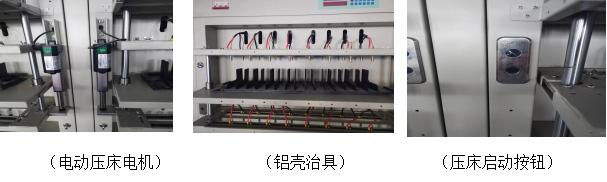

32-channel electric press device is used in one group.

Each device can perform constant current constant voltage charging and constant current discharging test on 128 batteries within the voltage range.

Constant current-constant voltage power supply is adopted, and the switch between constant current and constant voltage is shock-free, which is especially suitable for the charging requirements of lithium-ion batteries.

The device adopts AVR single-chip computer as the control center, and cooperates with the external sampling circuit. It can be controlled by the upper computer. When connected to the computer for work, it can save the complete charge-discharge curves of all channels, and it can also be separated from the upper computer. Complete constant current constant voltage charging, constant current discharging test, and time sorting work through panel operation.

Each battery has its own independent constant current constant voltage source, forming a loop and not affecting each other.

An LED is installed on each battery clamp to indicate the working status. After discharge is completed, it can be used to indicate battery capacity sorting.

Real-time detection of each battery voltage. When charging, first constant current charging, when the battery voltage reaches the set value, it will smoothly switch to constant voltage charging, and the charging will end when the set time or current termination condition is reached. During constant current discharge, when the battery voltage is lower than the set value, the discharge is terminated, and the corresponding battery indicator lights up.

It has power-off protection function and can continue to run the original working process after power-on.

The host computer can set 32 step parameters and 256 cycles. Each host computer can connect to 1-15 single-chip machine systems (recommended less than 10 sets).

Supporting software functions.

Use a graphical operation interface to display data such as voltage, current, time, and capacity of each battery, and use different colors to display the corresponding working status and abnormal conditions.

Arbitrary segment battery capacity display (up to 100 segments).

Data points can be recorded according to the changing conditions of voltage, current and time to form complete charge-discharge curve data, and the time interval of curve data points is ≤10 seconds.

Battery sorting function based on multiple conditions (capacity, time, open circuit voltage, discharge platform, etc.).

Automatically calculate constant current charging rate, capacity loss, discharge efficiency, average voltage, median voltage and other data.

Operator permission setting, hierarchical operation.

Charge-discharge curve and cycle chart can be displayed.

| No. | Item | Parameter |

|---|---|---|

| 1 | Device Channel Number | Total 128 channels |

| 2 | Working Flow Control Mode | Cabinet Control |

| 3 | Charging Mode | Constant Current, Constant Voltage |

| 4 | Charging Termination Condition | Voltage, Current, Time, Capacity |

| 5 | Discharge Mode | Constant Current |

| 6 | Discharge Termination Condition | Voltage, Time, Capacity |

| 7 | Sampling Inspection Cycle | ≤5s |

| 8 | Voltage Measurement Range | 0~5V, Resolution 1mV |

| 9 | Battery Voltage Range | Charging: 0~4.5V, Discharging: 4.5~2V |

| 10 | Constant Voltage Range | 3~4.5V |

| 11 | Voltage Accuracy | ±(0.05%RD+0.1%FS) |

| 12 | Current Range | Charging 0.05-30A, Discharging 0.05-30A, Resolution 1mA |

| 13 | Current Accuracy | ±(0.1%RD+0.1%FS) |

| 14 | Time Range | Set arbitrarily within 0-30000 minutes, time unit is min |

| 15 | Time Accuracy | ≤±0.1% |

| 16 | Clamp Type | Quick Press Down Type |

| 17 | Battery Spacing | Approx. 78mm |

| 18 | Communication Mode | RS485, Baud Rate 57600 |

| 19 | Device Startup Current | About 60A when air switch is closed |

| No. | Name | Material | Model | Quantity |

|---|---|---|---|---|

| 1 | Test Probe | Gold-plated Brass | 30A | 2 |

| No. | Name | Material | Model |

|---|---|---|---|

| 1 | Test Probe | Gold-plated Brass | 30A |

| No. | Name | Quantity/Unit | Specification |

|---|---|---|---|

| 1. | Open-end Wrench | 8mm-10mm | 1 piece |

| 2. | Open-end Wrench | 10mm-12mm | 1 piece |

| 3. | Open-end Wrench | 12mm-14mm | 1 piece |

| 4. | Open-end Wrench | 14mm-17mm | 1 piece |

| 5. | Phillips Screwdriver | 6*150mm | 1 set |

| 6. | Adjustable Wrench | 150mm | 1 piece |

| 7. | Needle-nose Pliers | 150mm | 1 piece |

| 8. | Watch Screwdriver Set | 6-piece set | 1 set |

Working environment temperature: Temperature: 0-40℃.

Relative humidity: 30%~75%.

Device size: Approx. 1750mm×600mm×1840mm(L×W×H).

Device weight: Approx. 300Kg.

Power supply: Three-phase four-wire system, AC380V±5%, 50HZ, power: Approx. 7KW.

Prev :

没有了!Next :

Laser sealing machine